LPCE-2 Integrating Sphere Spectroradiometer LED Testing System is for single LEDs and LED lighting products light measurement. LED’s quality should be tested by checking its photometric, colorimetric and electrical parameters. According to CIE 177, CIE84, CIE-13.3, IES LM-79-19, Optical-Engineering-49-3-033602, COMMISSION DELEGATED REGULATION (EU) 2019/2015, IESNA LM-63-2, IES-LM-80 and ANSI-C78.377, it recommends to using an array spectroradiometer with an integrating sphere to test SSL products. The LPCE-2 system is applied with LMS-9000C High Precision CCD Spectroradiometer or LMS-9500C Scientific Grade CCD Spectroradiometer, and A molding integrating sphere with holder base. This sphere is more round and the test result is more accruacy than the traditional integrating sphere.

Measures:

• Colorimetric: Chromaticity coordinates, CCT, Color Ratio, Peak Wavelength, Half Bandwidth, Dominant Wavelength, Color Purity, CRI, CQS, TM-30 (Rf, Rg), Spectrum Test

• Photometric: Luminous Flux, Luminous Efficiency, Radiant Power, EEI, Energy Efficiency Class, Pupil Flux, Pupil Flux Efficiency, Pupil Factor, Cirtopic Flux, Plant Growth Lamp PAR and PPF

• Electrical: Voltage, Current, Power, Power Factor, Displacement Factor, Harmonic

• LED Light Decay Test according to LM-80: Flux VS time, CCT VS time, CRI VS time, Power VS time, Power Factor VS time, Current VS time and Flux Efficiency VS time.

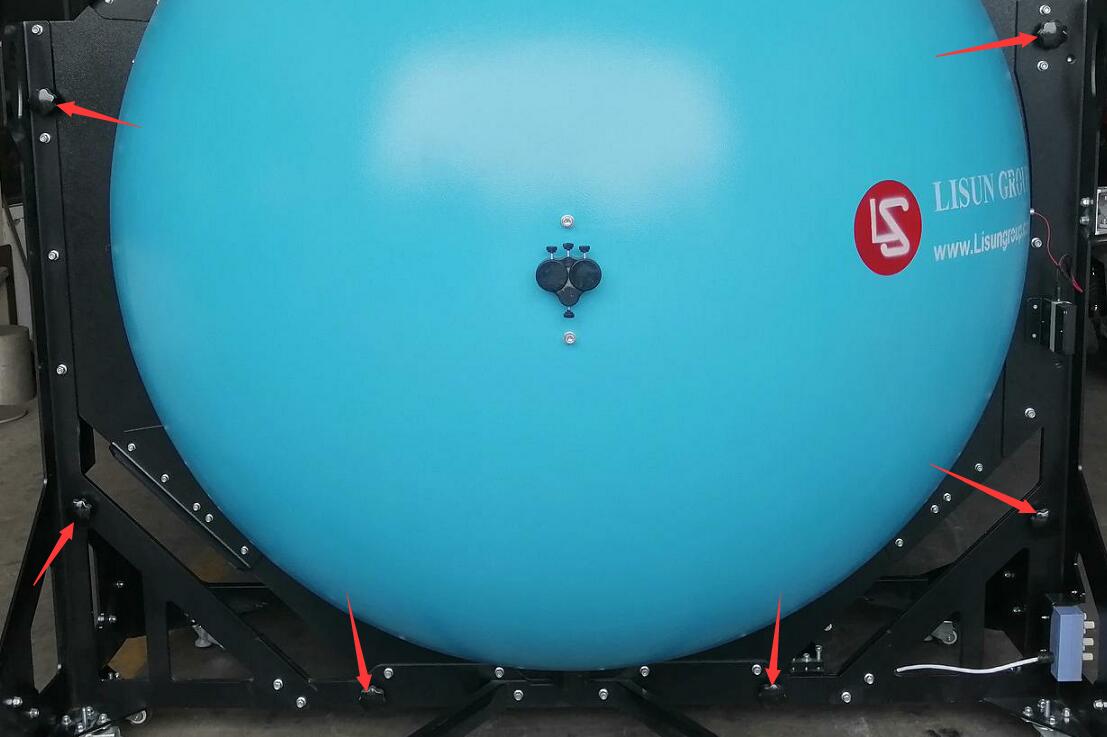

Q1:The big sphere can’t be openned.

A1:We put two screws to lock the sphere during the transportation to avoid opening. Please just remove these two screws.

Q2:How to disassemble the big integrating sphere into two parts to facilitate transportation.

A2:First of all, it is not recommended to disassemble and transport it, as this will easily stain the internal coating. If you have to, please remove all the large black hand screws to disassemble the big integrating sphere into left and right parts. NOTE: Do not remove any other kind of screws. During transportation, please be careful not to dirty the internal coating of the integrating sphere.

Q3:The communication between software and hardware (LMS-9500C spectroradiometer, AC power source, DC power source, Power meter, etc) is failed.

A3:See the figure below. LMS-9500C is powered by a power adapter. Please connect the power adapter provided by LISUN. Otherwise, it may not start or communication may be abnormal.

LMS-9500C power adapter

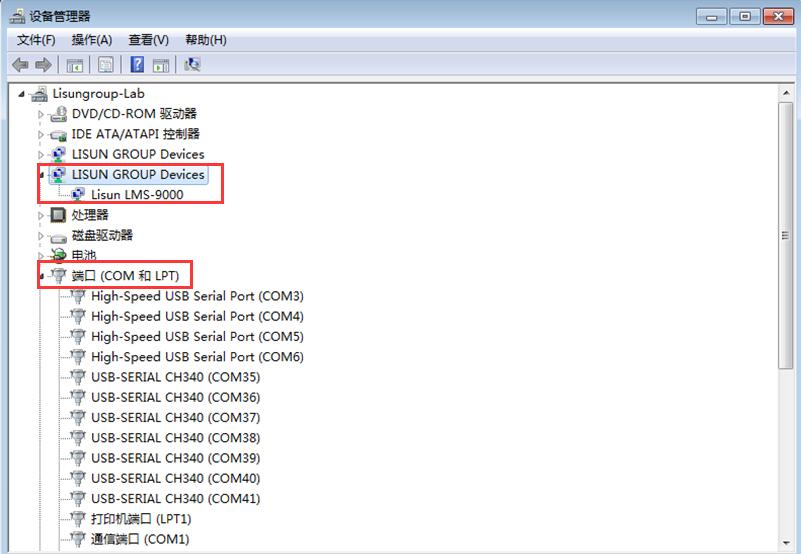

There are two drivers need to be installed. Please confirm that you installed both successfully.

Please connect the two USB cables of the system to the blackUSB2.0 ports of the computer.

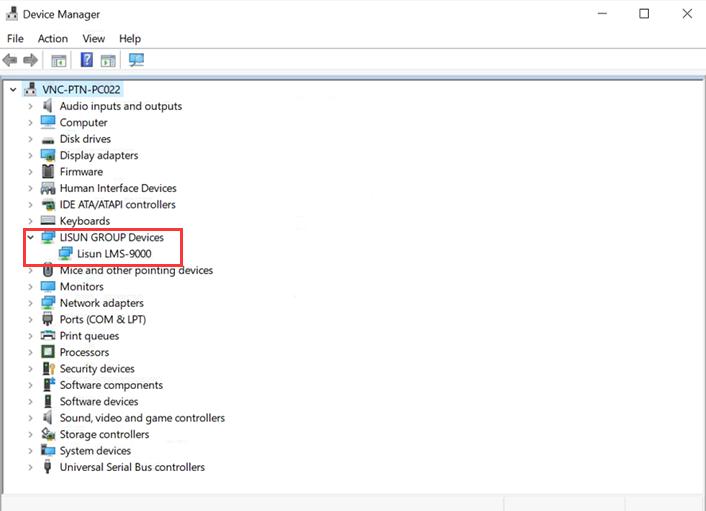

Enter the “Device manager” of the computer (Please google it if you don’ know how to enter this interface), and you can see LMS-9000 model and more COM ports there, then it means the communication is ok.

Q4:How to update the latest driver for LMS-9500.

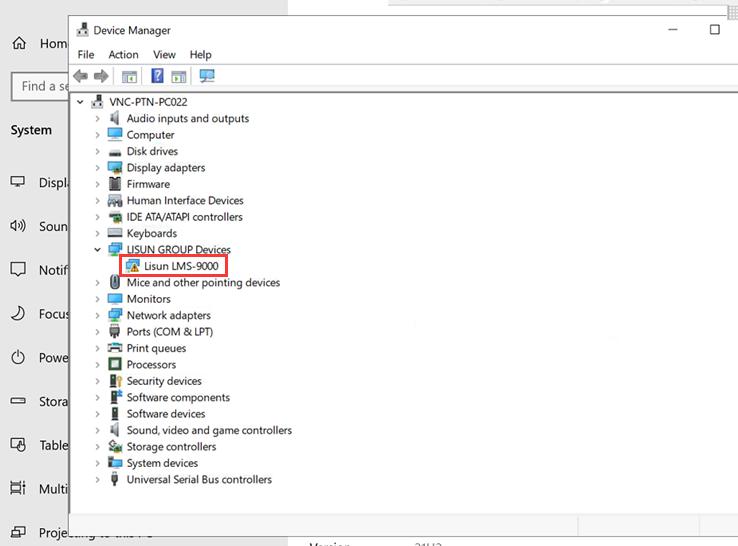

A4:Enter “Device manager” of the computer. You can find the LMS-9000 device here:

Right click LMS-9000 and select “Uninstall device”:

Right click LMS-9000 and select “Uninstall device”:

Check “Delete the driver software for this device” and click “Uninstall”:

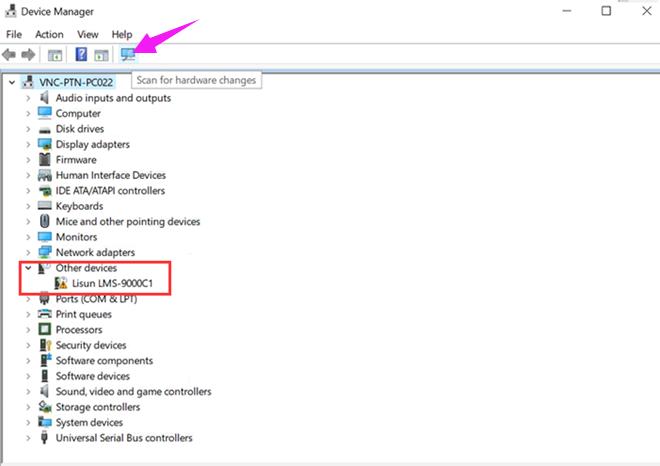

Click “Scan for hardware changes”. The LMS-9000 is shown as “Unknown device”:

Click here to downloadn the the new driver here. Or contact LISUN engineer for it.

Double click to install it:

Then you can find the LMS-9000 is ready to use.

Q5:A parameter on the front panel of digital power meter shows a negative value.

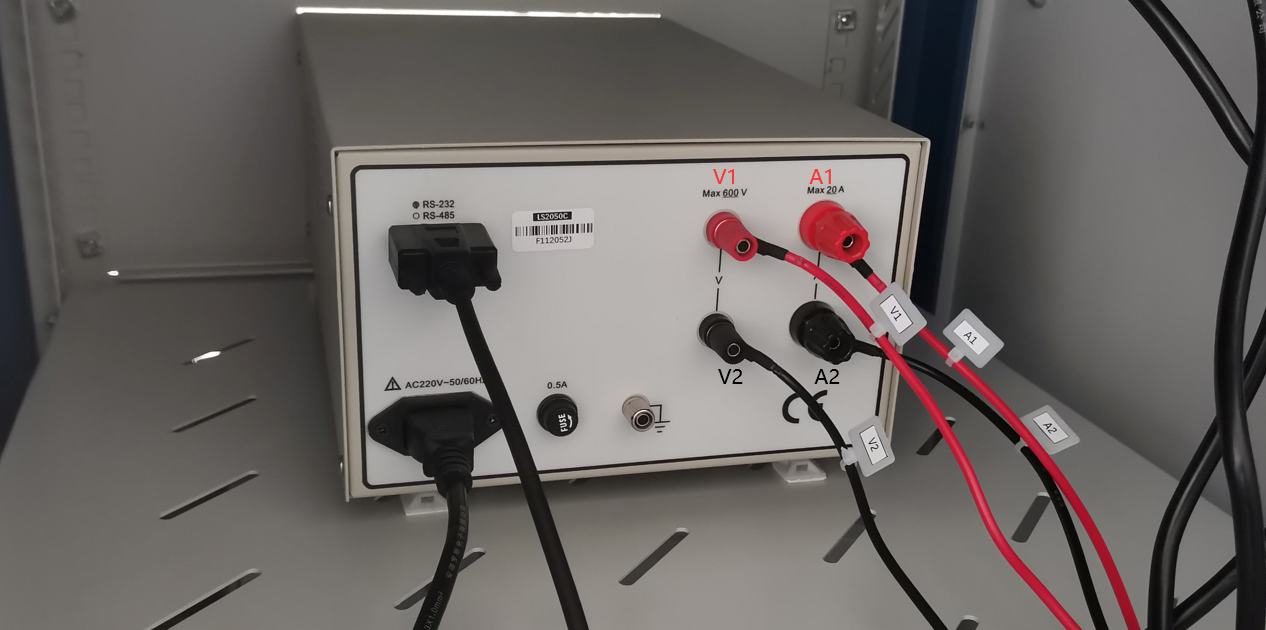

A5:Please check the wiring on the back of the power meter and confirm that the four wires A1 A2 V1 V2 are connected to the correct terminals.

Q6:The standard lamp can’t be turned on automatically.

A6:① Confirm that the AC/DC switch is at DC.

② Check “Auto power on” on the calibration interface. Input the correct voltage and current according to the calibration certification.

③ Confirm that the filament of the standard lamp is still good.

Q7:The installation direction of the sample.

A7:The integrating sphere holder base can be installed on the top or bottom of the integrating sphere. When installed at the bottom of the integrating sphere, all lamps should be installed with the emitting direction facing directly upward, as shown below:

On the contrary, if the holder base is installed on the top of the integrating sphere, all lamps should be installed with the emitting direction facing directly downwards.

On the contrary, if the holder base is installed on the top of the integrating sphere, all lamps should be installed with the emitting direction facing directly downwards.

Q8:Test results are not correct.

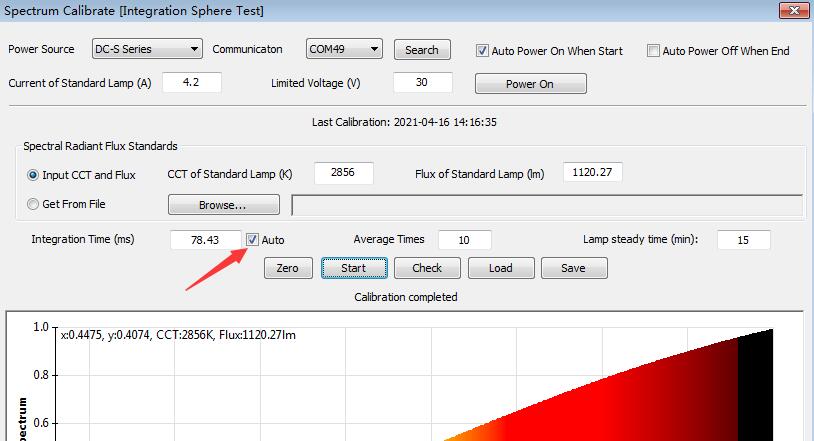

A8:① Confirm that the standard lamp is still in valid time (Its valid time is only 1 year). Recalibrate the system. After calibration, confirm that the CCT and flux values displayed are close to the values that on the certification (CCT within 2k, and flux within 2 lumen).

Note: If the system is used frequently, it needs to be calibrated once a week. If the system is not used for a long time, it can be calibrated before next use. If too long has passed since the last calibration, the test data will be inaccurate.

② Confirm that you are using the correct assistant lamp revision coefficient. Bared light sources and small luminaires donot need to use assistant lamp revision coefficient. That is to say, the coefficient is 1. But big luminaires need to use assistant lamp to generate this coefficient (Please refer to the user manual for the detailed steps), and the coefficient is bigger than 1.

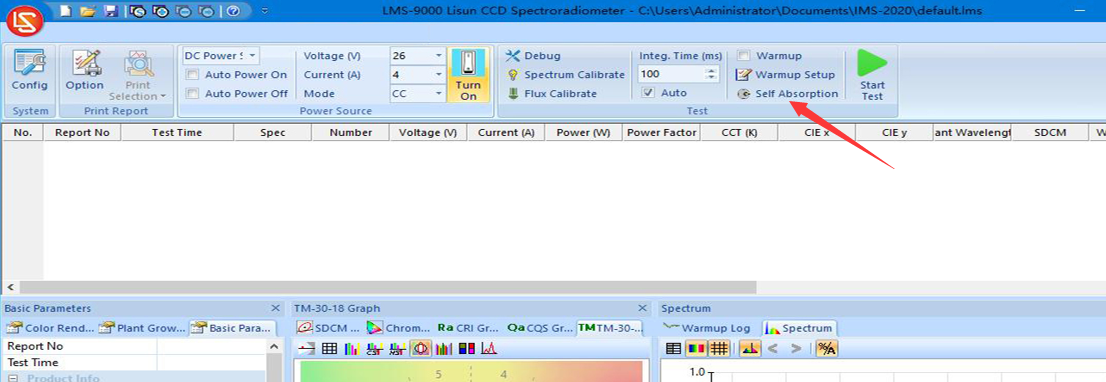

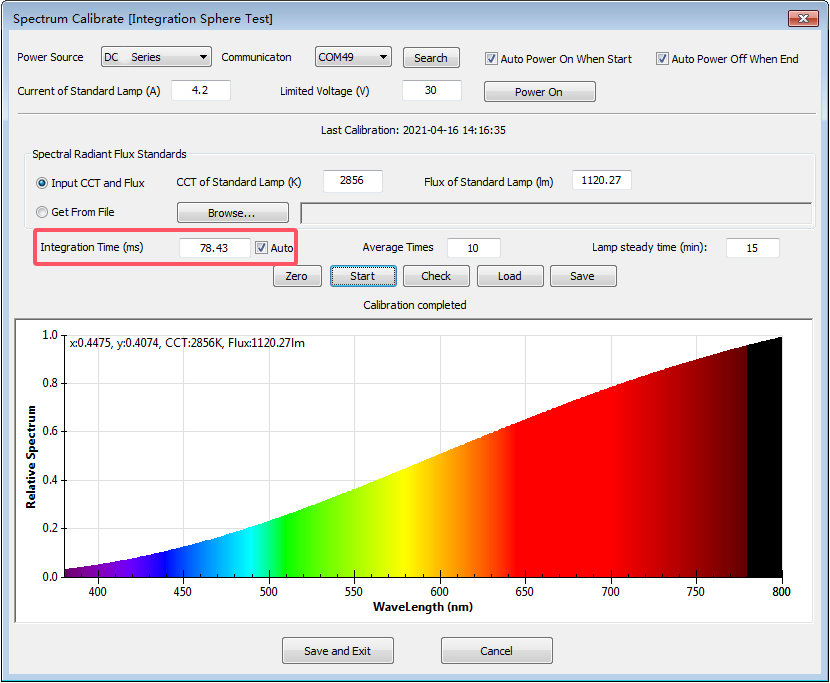

③ Please always check “Auto” for the “integration time” when you calibrate the system and run a test.

Calibration interface:

Measurement interface:

④ When using a big integrating sphere to measure small lights, the signal may be too weak; When using a small integrating sphere to measure big lights, the signal may be too strong. This may also lead to inaccurate test results. Please choose an integrating sphere of appropriate size for testing according to the actual situation.

⑤ Note: When you test big luminaires or directional luminaires, you need to use assistant lamp. Then the test results will be closer to the actual values, but there will still be errors. Such luminaires can be tested in a darkroom using a goniophotometer to obtain more accurate photometric parameters.

⑥ If the integrating sphere is used for too long, or care is not taken to protect the internal coating of the integrating sphere, resulting in serious damage to the internal coating of the integrating sphere, or a darker color, it will also lead to inaccurate test data.

Q9:During calibration or testing, the software prompts that the signal is too weak.

A9:The LMS-9000 spectroradiometer receives the optical signal from the integrating sphere through optical fiber. When calibrating or testing, please confirm that the standard lamp or sample lamp is normally turned on, and the optical fiber is properly connected to the integrating sphere. Otherwise, the software will prompts that the signal is too weak. In addition, the optical fiber should not be bent too much, otherwise it may cause the fiber to break and cause problems with optical signal transmission.

Q10:Software can’t get electrical parameters.

A10:Please confirm that you selected the correct power meter model and the correct COM port. See the figure below:

If your power meter is only for AC, so please select DC power supply as the DC power meter if your sample is DC lamp. See the figure below:

Q11:DC samples can’t be turned on automatically.

A11:Please confirm that the voltage and current of the sample is within the limit of the DC power supply. For example, the limit voltage is 30V and the limit current is 5A for DC3005 DC power supply.

If the sample needs constant current (CC), you need to input its rated current and a high enough voltage.

If the sample needs constant voltage (CV), you need to input its rated voltage and a high enough current.

Q12:How to maintain an integrating sphere.

A12:① The internal coating of the integrating sphere is very important, so you must wear white gloves whenever you are working inside the integrating sphere to avoid staining the internal coating of the integrating sphere.

② When the integrating sphere is not in use, keep it closed to prevent dust from entering. If dust gets in, use a blower to blow it out. Please do not use any contact materials to clean the inside of the integrating sphere, otherwise the coating may be damaged.

③ If the sample, etc. falls, causing a small area of coating inside the integrating sphere to peel off, please contact us. We can send you a small amount of paint free of charge to repair the peeling parts.

Q13:The software says that the signal is too weak to test when measuring a weak light source.

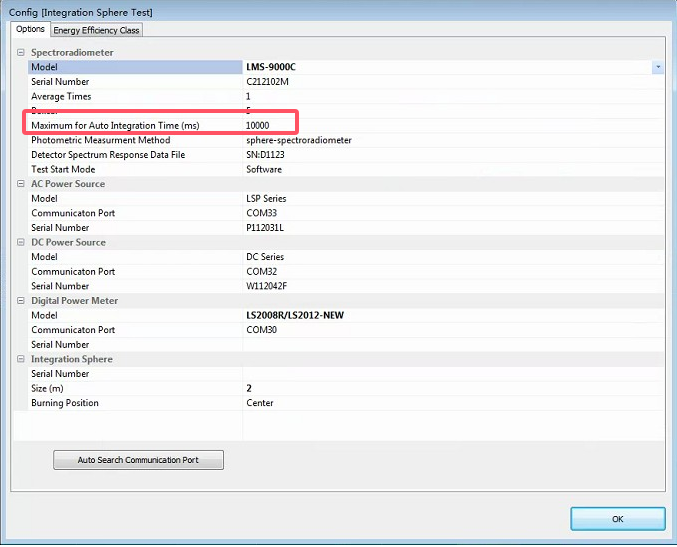

A12:The default maximum integration time is 2000ms, which can basically meet 99% of the test requirements. If you occasionally need to test a very weak light source and the software prompts “Signal is too weak” to test, please increase the maximum integration time refer to the figure below and try the test again:

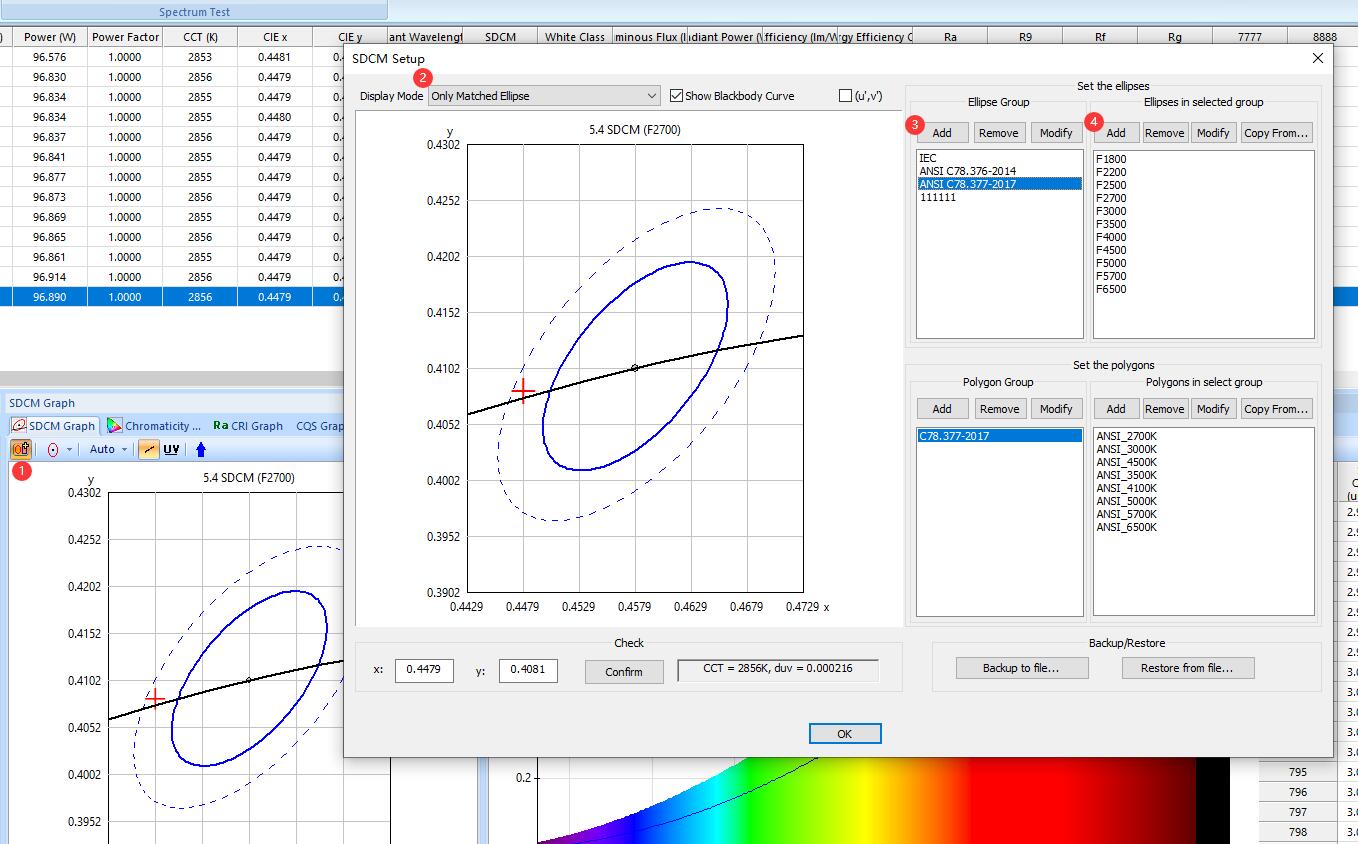

Q14:How to manually add industry standard SDCM McAdam ellipse?

A14:The LMS-9000C software has built-in commonly used standards such as IEC and ANSI ellipse for SDCM. If you need to add other industry standards, please add them as shown below: 1. Click Add, 2. Select the display mode, 3. Click Add standard group, 4. Click Add ellipse.

Then fill in the specific information of the ellipse in the figure below. The center point coordinates x, y, angle θ, the ellipse’s long and short radii a, b, and the ellipse size R1, R2 are all given by the customer, and then g11, g12, g22 are calculated according to the formula and filled in.

SDCM McAdam ellipse

The following is the fomula for g11 g12 and g22:

Then continue to add all the ellipses. Note: Manual calculation is cumbersome. You can edit the EXCEL table and write the formula for automatic calculation, or you can contact us directly to obtain the EXCEL table.

Then continue to add all the ellipses. Note: Manual calculation is cumbersome. You can edit the EXCEL table and write the formula for automatic calculation, or you can contact us directly to obtain the EXCEL table.

Q15:The automatic integration time reaches the set maximum integration time during calibration or testing.

A15:If the automatic integration time reaches the maximum integration time set during calibration or testing, there is a problem with the calibration and testing. Please check whether the connections of each part are correct. If there is still a problem, please contact LISUN engineers.

The following is the maximum integration time set on the software:

Maximum for auto integration time

Auto integration time for calibration

The following is the automatic integration time required for the test after the test is successful:

Auto integration time for testing

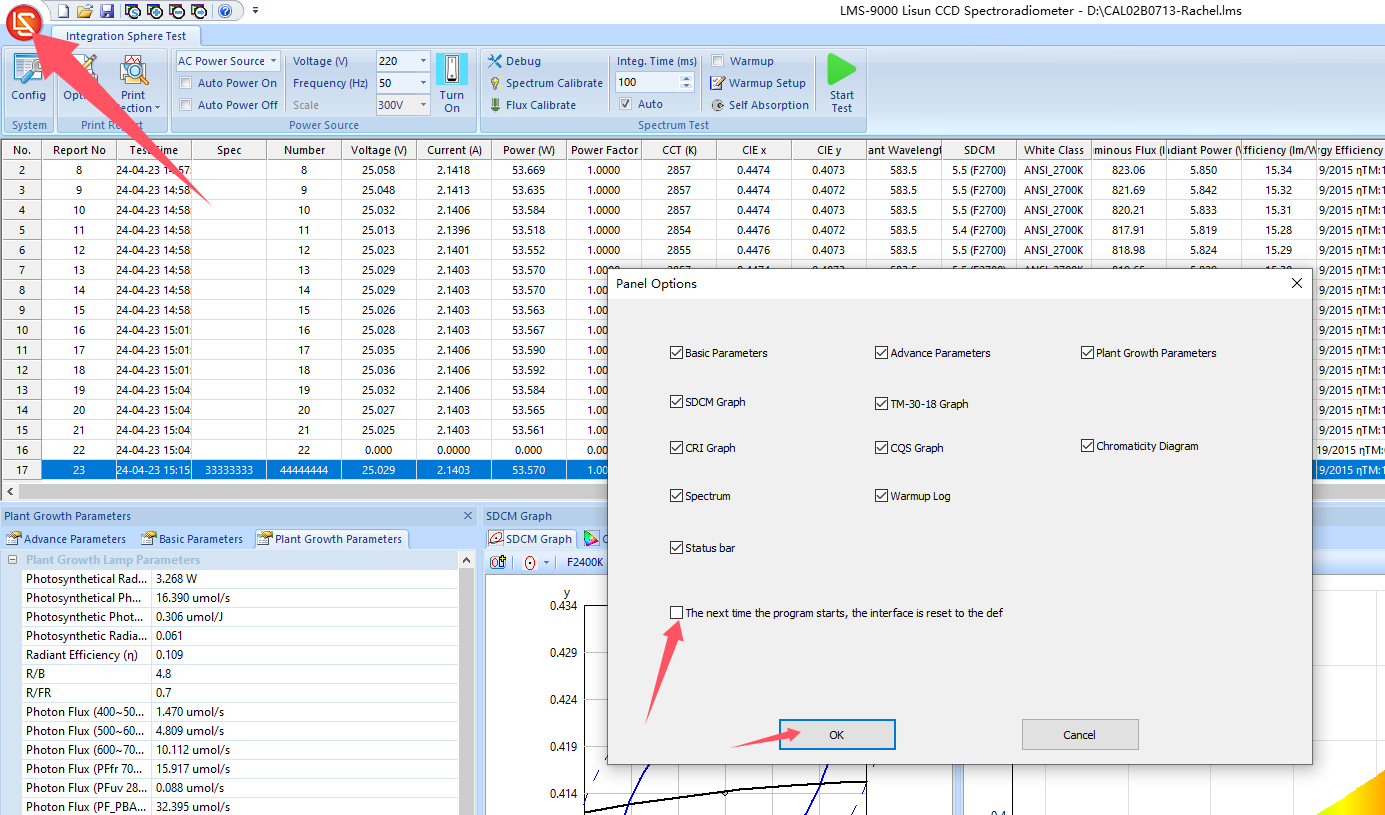

Q16:All modules on the main interface of the software can be dragged, deleted, etc. How to restore the initial interface layout?

A16:Click the software logo in the upper left corner and select “Panel Options”. Check the option marked in the figure below to restore the initial layout the next time the software is started.

LMS-9000C software panel options

Q17:After installing the new version of the software, the calibration and test results are abnormal.

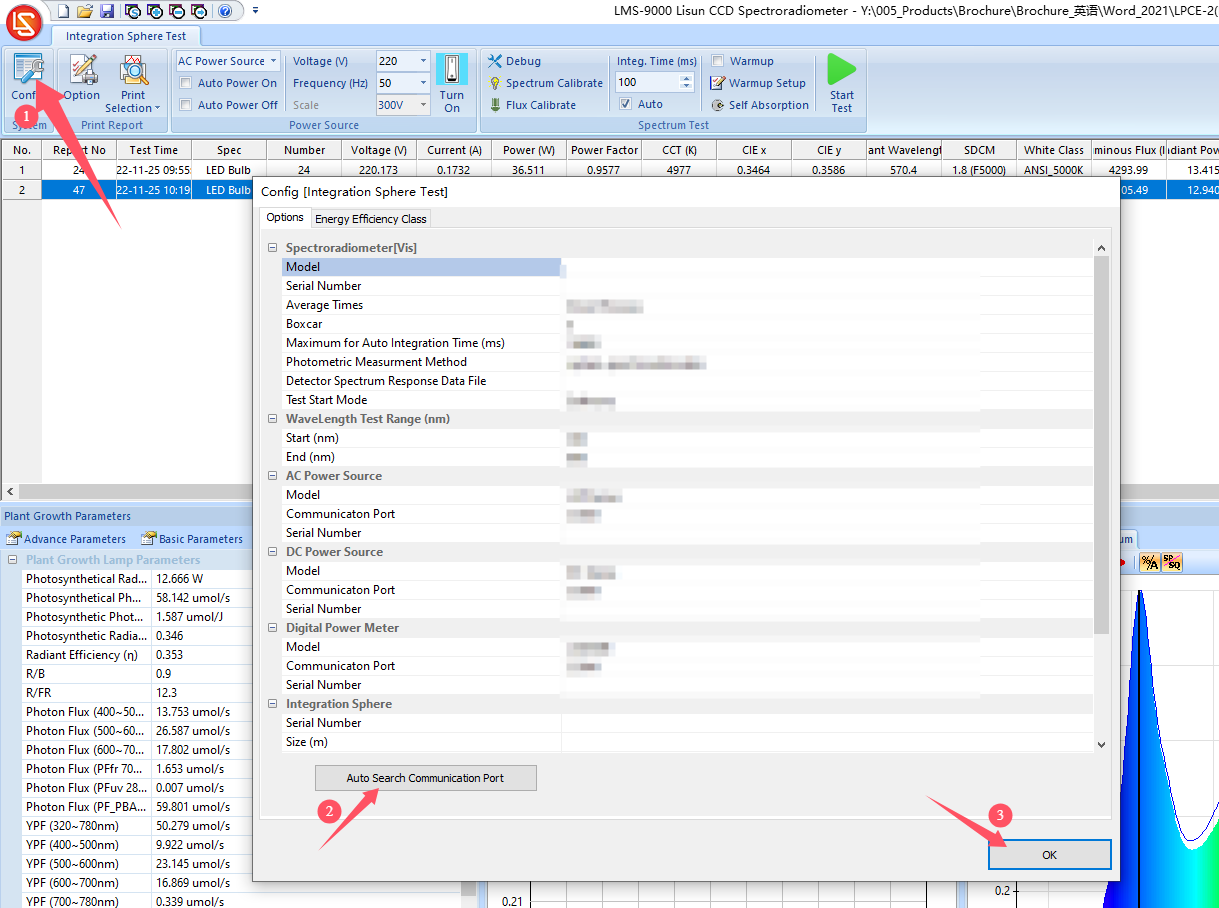

A17:When there is a new version of the software. after installing the new version of the software, please go to the “System Configuration” interface to communicate with all hardware, including the spectroradiometer, and then go to the calibration test. Otherwise, the calibration test may be abnormal.

LMS-9000C system configuration interface

Q18:Too many test reports are saved in the same database file, which affects the running speed of the software.

A18:If you always open the same database file by default, after a long time, there will be too many test reports saved in the file, which will affect the software running speed and make it inconvenient to find a certain test report. It is recommended to create different database files for different samples to facilitate saving and searching. Note: Every time the software is opened, the last database file is opened by default. If the file has changed, the software will automatically pop up the dialog box for creating a new database file, and you can directly create a new database file.

Click the button in the figure below to create a new database file:

LMS-9000C create a new database file

Q19:How to switch the interface display language of LSP series AC power supply?

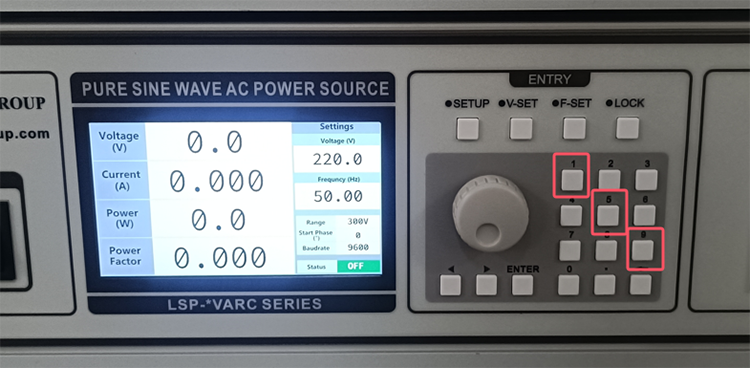

A19:See the figure below. Press the number keys 1, 5, and 9 at the same time to switch the interface display language between Chinese and English:

Change the diplay language of LSP series power supply

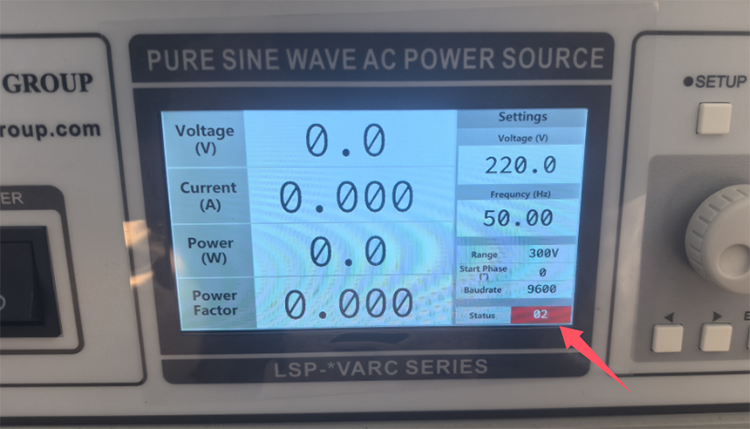

Q20:LSP series AC power supply, alarm after output. Alarm code 02 in the lower right corner.

See the figure below:

LPS Series AC Power Supply 02 Alarm

A20:When the output is short-circuited, the current is over-limited, or the power is over-limited, the LSP series AC power supply will automatically cut off the output to protect itself and display the alarm code 02. Please turn off the LSP power supply output and check all the wiring of its output sample to eliminate the output short-circuit, and then just restart the output. If the current or power of the connected sample exceeds the upper limit of the LSP power supply, you need to purchase a larger power supply.

Lisun Instruments Limited was found by LISUN GROUP in 2003. LISUN quality system has been strictly certified by ISO9001:2015. As a CIE Membership, LISUN products are designed based on CIE, IEC and other international or national standards. All products passed CE certificate and authenticated by the third party lab.

Our main products are Goniophotometer, Integrating Sphere, Spectroradiometer, Surge Generator, ESD Simulator Guns, EMI Receiver, EMC Test Equipment, Electrical Safety Tester, Environmental Chamber, Temperature Chamber, Climate Chamber, Thermal Chamber, Salt Spray Test, Dust Test Chamber, Waterproof Test, RoHS Test (EDXRF), Glow Wire Test and Needle Flame Test.

Please feel free to contact us if you need any support.

Tech Dep: Service@Lisungroup.com, Cell/WhatsApp:+8615317907381

Sales Dep: Sales@Lisungroup.com, Cell/WhatsApp:+8618117273997

Your email address will not be published. Required fields are marked *